How Automation Can Improve Decision Making for Aircraft Parts Purchasing

By Erkki Brakmann

Given the current demand shock facing commercial aviation due to the COVID-19 pandemic, the squeeze has been felt across the board from commercial and revenue teams through to operations, customer service and pilots.

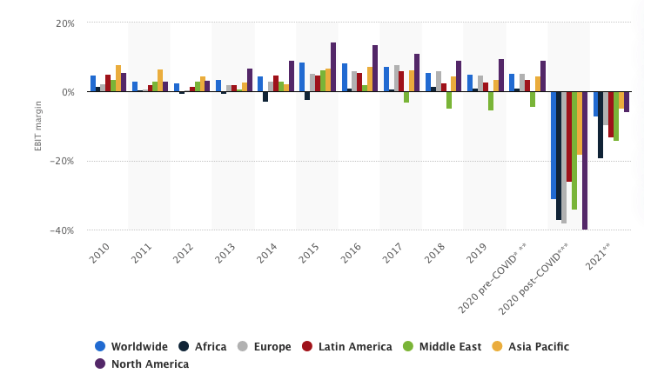

The line between success and failure has always been razor-thin, even before COVID-19. As reflected below in the graph from Statista, the average EBIT of a commercial airline was 5.5% pre-COVID 2020, before shrinking to -31% post-COVID. In comparison, the average EBITDA across all industries is 15.25%.

Given these dire circumstances, every penny matters for airlines as they learn how to do more with less. This is especially true on the maintenance, repair and overhaul (MRO) side of aviation, which represents up to 12 to 20% of an airline’s operating costs.

Fortunately, like many other facets of business, new automation and workflow tools are replacing manual processes, making it possible to run more efficiently and cost-effectively.

“Robotics and AI helped [companies] keep their businesses going. And that’s going to continue to have long-lasting impacts on where the jobs are going to be in the future,” said Susan Lund, Partner, McKinsey Global Institute.

Airlines Adopt Automation & New Technologies

One of the spill-over effects of the pandemic and underlying demand shock has been airlines have been focusing on investigating new technologies and procedures.

A report from Future Travel Experience (FTE), and the Airline Passenger Experience Association (APEX) found that 63.7% of respondents expect the COVID-19 crisis to accelerate innovation and digital transformation projects within their organization, 19.2% expect their organization to continue with their pre-coronavirus plans, and only 17.1% expect innovation and digital transformation projects to be delayed.

One of the major digital transformation trends occurring at airlines across the globe is the adoption of automation technology. In his 2021 Airline Digital Trends Report, Iztok Franko, Founder of Diggintravel, identifies robotic process automation (RPA) as an emerging technology.

Franko writes, “AirAsia announced last year that they will start implementing robotic process automation (RPA). The airline plans to automate mundane and repetitive tasks, which will free up their workforce to focus on more complex tasks that require critical thinking and experience-based judgment.”

Applying Human Intelligence Where it is Needed

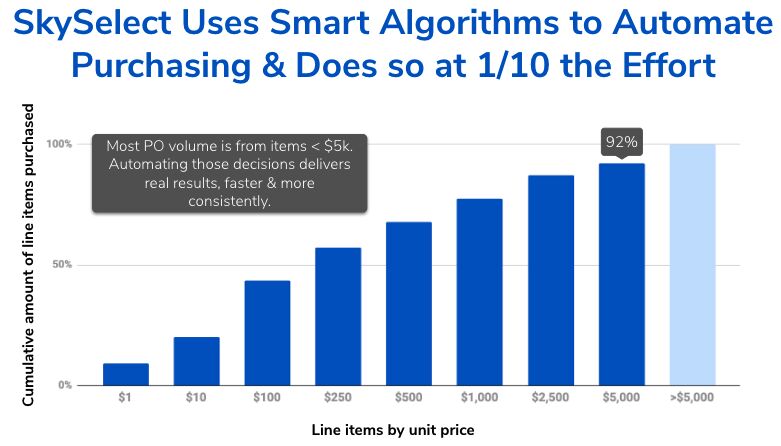

This has the potential to specifically impact MRO, where the majority of parts purchasing is done for tiny minuscule parts. As represented by the graphic below, more than 90% of aircraft parts bought cost $5,000 or less.

It’s never been about machines replacing mankind, but about augmenting it. It’s about machines and automation freeing up time so people can focus their time and energy on more important tasks where human intelligence is needed most. In the case of airlines and MROs, it’s allowing planners to focus on that 5-10% of spare parts where the right moves can directly impact the bottom line by reducing costs.

SkySelect’s own data shows a potential for a 30-50% productivity increase from leveraging algorithmic decision-making to streamline and optimize the procurement process for both buyers and sellers. This is a substantial improvement from a slow, tedious and error-prone process. Automating those decisions delivers real results, faster and more consistently.

With the manual nature and scale of the process, airlines are often unable to evaluate the quality of decisions. A more automated process not only facilitates high-quality decisions 100% of the time, it also captures all the decision data so that it can be tracked and analyzed. This has a compounding effect, because the more data you capture the more automation you can apply through machine learning and artificial intelligence.

By successfully implementing automation into operational processes, airlines can not only survive COVID-19, but position themselves well post-COVID by having the right workflows in place to capture the influx of demand by keeping their fleet running and focusing on the most impactful decisions.